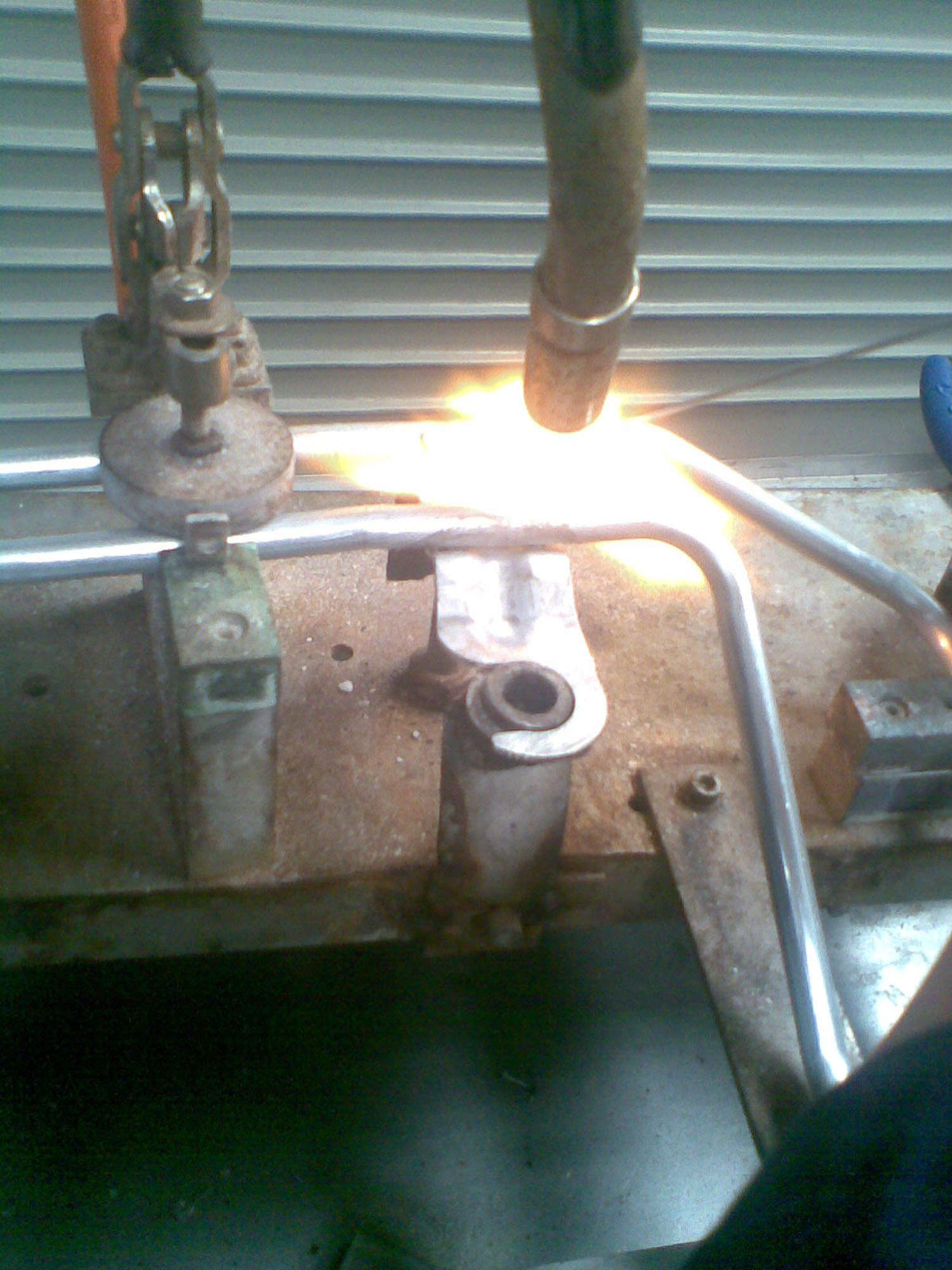

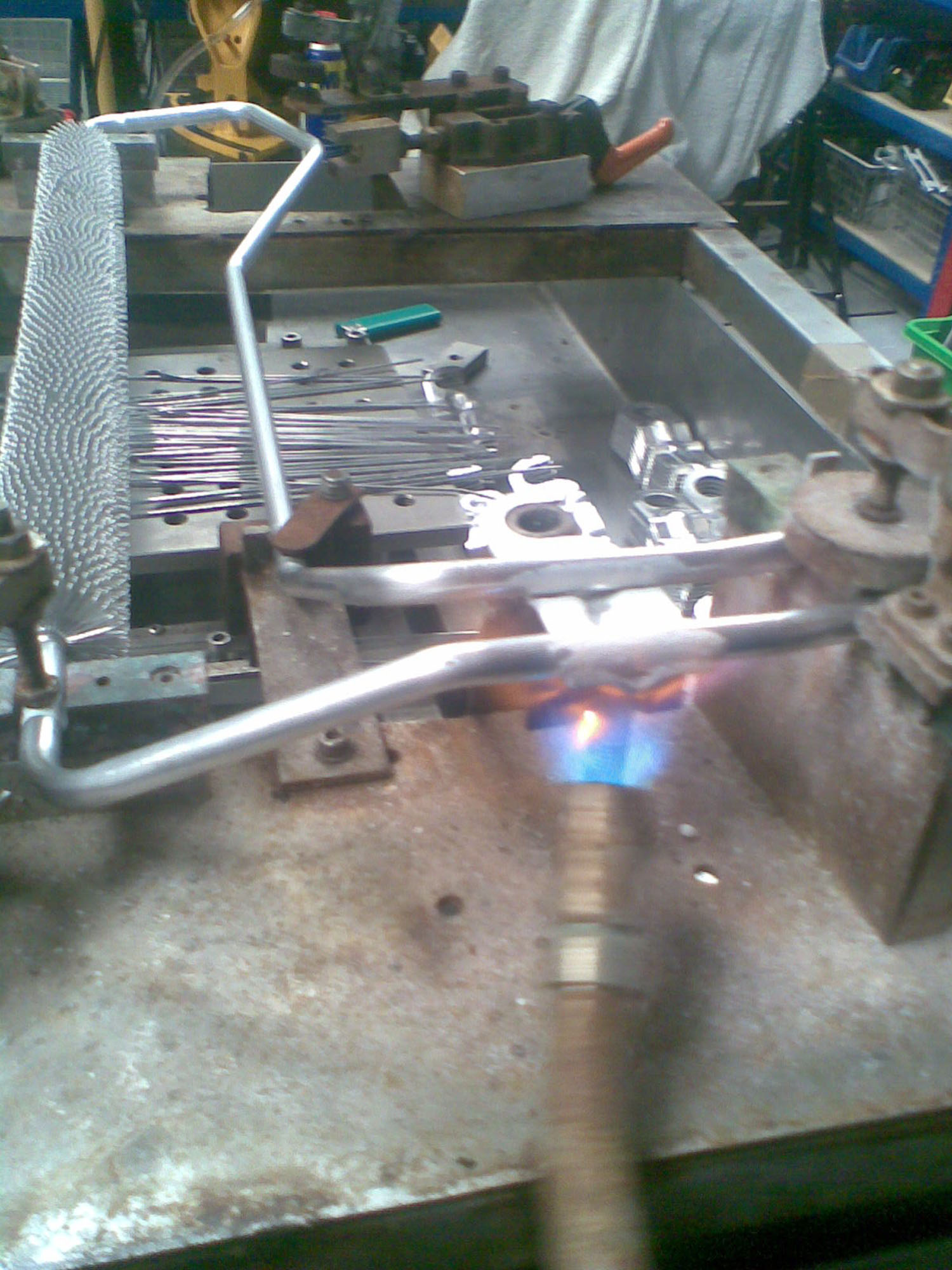

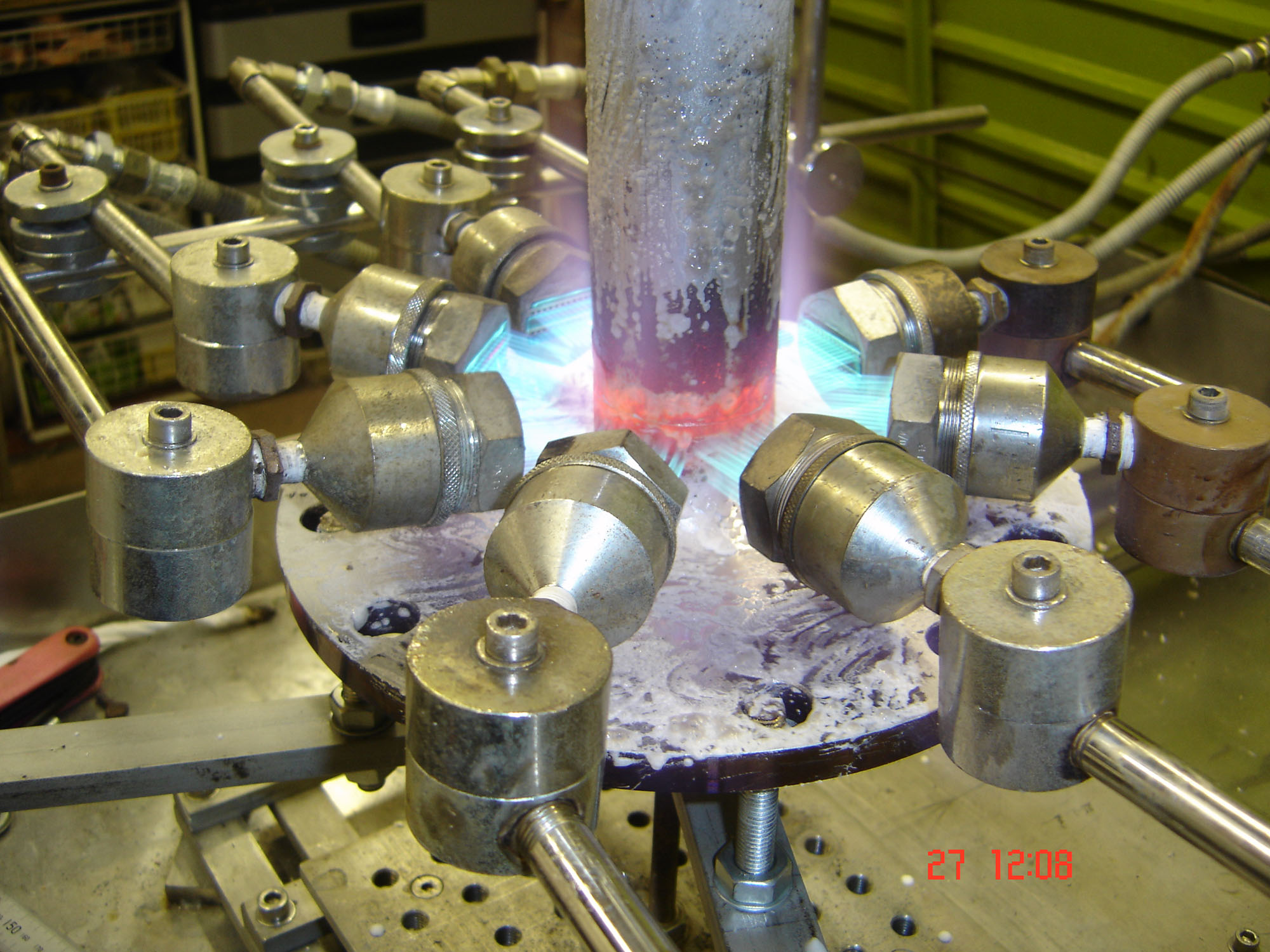

Are you currently using FLAME / TORCH brazing in your process?

Are you considering FLAME / TORCH for a new process?

If the answer is YES whether your requirement’s are for manual OR mechanized flame brazing, then this web site is dedicated to you.

A flame is a heat source….the purpose of the flame is to raise the temperature of the material it touches to a sufficiently high enough temperature to enable a process to be carried out…what is the process? And what type of flame is required?

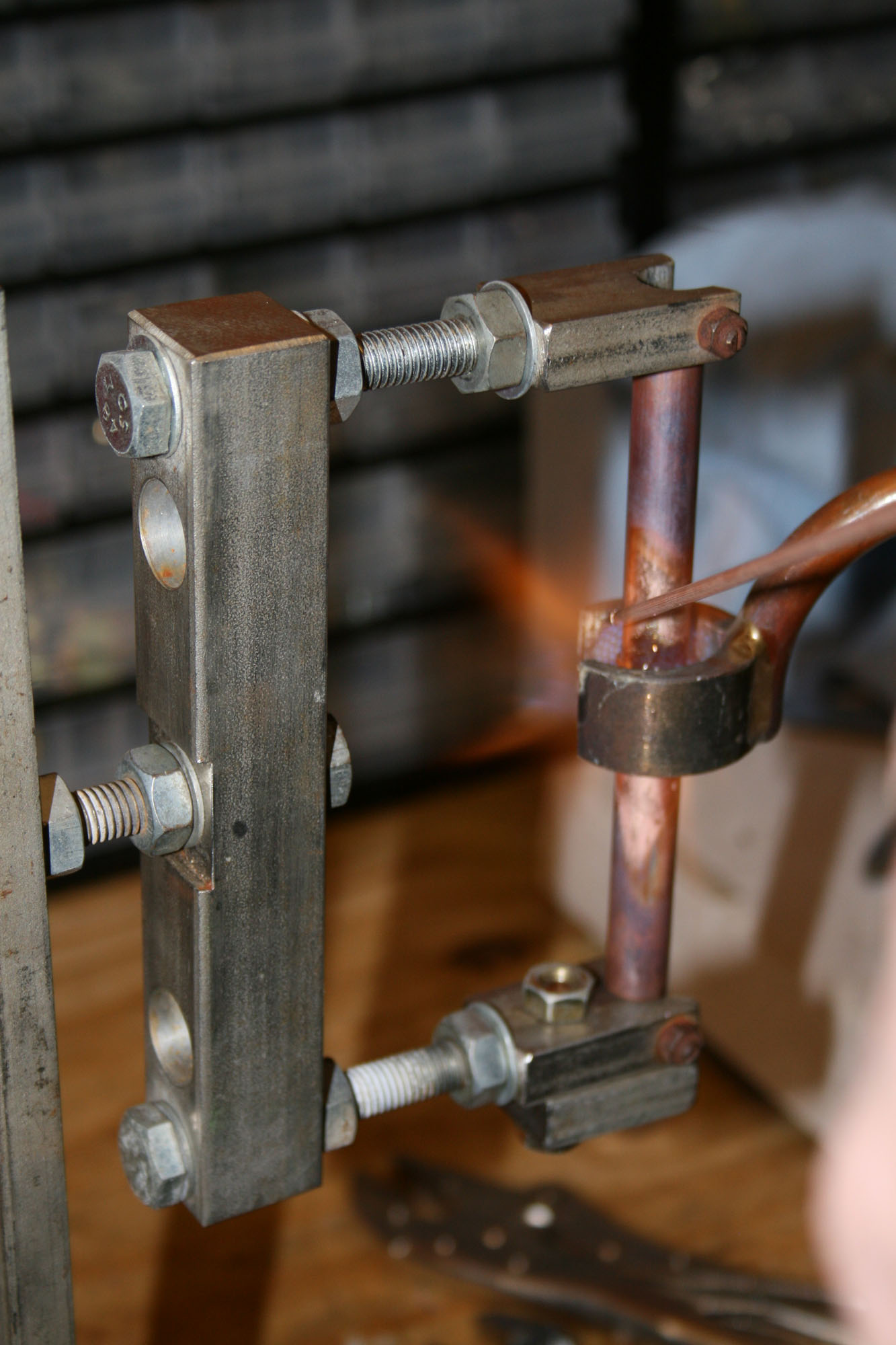

One such process is Flame Brazing (often referred to as Torch Brazing).

Brazing is a time/temperature process where the flame is the source of the temperature.

There are many other factors (apart from the nature and composition of the flame) that must be considered in order to carry out a flame brazing process successfully.

The objective of the end user who is carrying out the flame brazing operation is to make leak tight joints that pass what ever quality requirements their customer or customers customer specify.

Some simple questions:

Some simple questions:

Joint cleanliness……”How clean is clean?”

Joint design…………”How near best practice is the joint design and tolerances?”

Uniform Heating……”How uniform is the heating of the joint?”

Leak testing…………”How leak tight is leak tight?”

Process………………”How do you control the process?”

Process………………”How repeatable is the process?

There is probably scope to improve most flame brazing applications………But to what cost/benefit?

We look forward to discussing your requirements.

Contact us today:

e-Mail: derek.davies11@virginmedia.com / derekdavies@flamebrazing.com

Telephone: 00 44 (0)1625 850 890

Mobile: 00 44 (0)7810 100 749

…and start saving money!